Cymbal Production

The Art of Cymbal Making

At Mosico, our process is built on a philosophy that is unique to our company. We do things our way because it works for us, consistently delivering superior results. We believe, from decades of experience, that only a human being has the intuition and skill to create truly superior musical instruments.

For our professional series, every cymbal is crafted exclusively by hand. We use mechanical devices sparingly and only as aids to our artisans, never at the expense of sound or quality. These devices help remove strenuous physical labor, allowing our craftsmen to concentrate their talent and energy on creating instruments with the highest sound quality and consistency.

When crafting our mid-range cymbals, we introduce automated processes in the initial stages to ensure precision and efficiency. However, the final crucial steps are always refined by hand to guarantee a musical and articulate result.

Our value-class cymbals are formed with the aid of machines, which allows us to significantly lower production costs. This approach makes high-quality sound accessible to a wider audience, from students to aspiring professionals.

The true art of cymbal making lies in selecting the appropriate methods to achieve the desired goals. Whether we are striving to create the ultimate professional sound quality or aiming to achieve optimal value at a specific price point, our philosophy remains the same: combining tradition and technology to produce cymbals that inspire.

Traditional Hand Craftsmanship

Mixing the Elements: The Mosico B20 Difference

At Mosico, our cymbals begin with the finest B20 Bronze, an alloy composed of 80% copper and 20% tin. This material is widely regarded as the most suitable for crafting musical instruments due to its rich tonal properties.

The true magic, however, lies in a centuries-old, proprietary process that we use to treat the alloy. This crucial technique imparts the perfect balance of strength, durability, and flexibility. Without it, the bronze would be hard and brittle, rendering it as fragile as glass. This essential process is the key to unlocking the beautiful, musical sound of our cymbals, guaranteeing that every instrument we create is of the highest possible quality.

Casting: Forging the Foundation

The journey of our cast cymbals begins with the careful blending of metals. We melt and combine our high-quality copper and tin in a melting pot at a specific temperature. This precise process ensures all impurities are evaporated, creating a pure and potent alloy.

Once the mixture is perfected, it is poured into molds where it solidifies into what we call castings. These castings are the solid foundation of every Mosico cymbal, now ready for the next crucial step: “Heating.”

Heating & Rolling: The Art of Transformation

Our castings are first heated to temperatures between 700-800°C in our specialized ovens. Our skilled craftsmen ensure each piece is heated evenly, softening the alloy and preparing it for the next stage.

Once heated, the castings are processed under our rolling machine, which transforms them into flat metal discs known as blanks. These blanks undergo multiple heating and rolling cycles until they achieve the desired thickness. This process is crucial not only for shaping the metal but also for allowing the metal molecules to bond perfectly, which significantly enhances the alloy’s flexibility and durability.

After this step, the blanks are set aside to cool, ready for the next stage of their journey to becoming a Mosico cymbal.

Cutting: Defining the Shape

Once a blank has cooled, it’s heated again and placed in a specialized mold for shaping. After the blanks are precisely cut into their intended form, they officially become the primary cymbal shape.

Hammering: Forging Sound

Hammering is the first and most crucial step in shaping the unique voice of every Mosico cymbal. Our skilled artisans employ centuries-old techniques, using each strike to define the dark, complex, and musical qualities that set our cymbals apart. This intricate process demands a mastery of both skill and intuition.

For our handmade series, the sound is meticulously tuned by our experienced craftsmen. Each individual hammer hit shapes the cymbal’s profile and contributes to its unique character, ensuring that every instrument has a voice as individual as the musician who plays it.

Lathing: Shaping the Sound

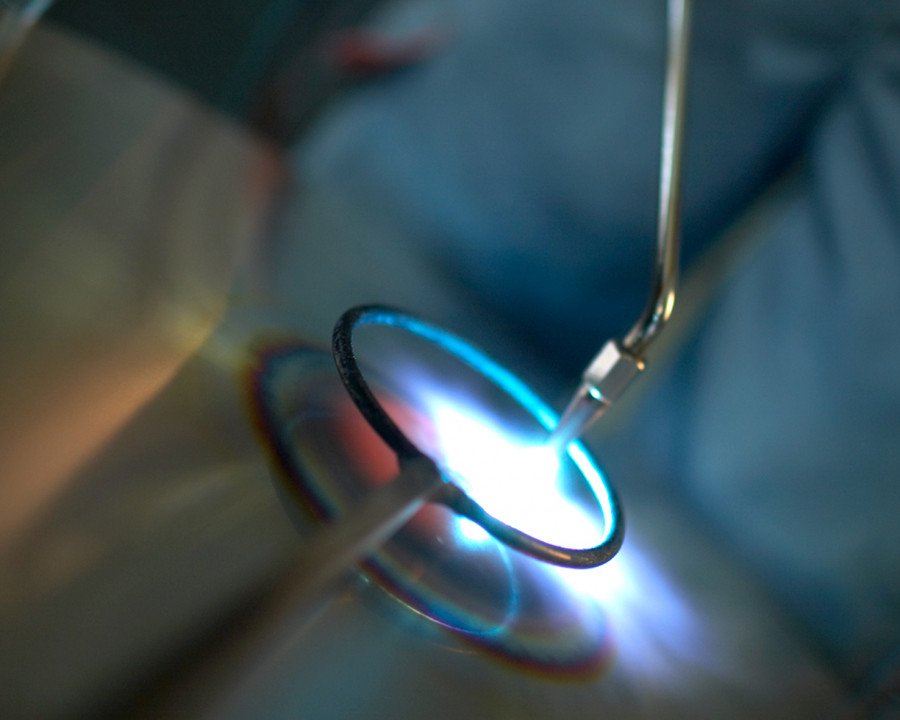

Lathing is another crucial phase in the cymbal-making process, and it has a direct and significant impact on a cymbal’s final sound. This important step requires a highly skilled craftsman.

During lathing, circular grooves are meticulously carved into the surface of the cymbal. These grooves are essential for allowing vibrations to travel more easily and freely across the metal, which ultimately gives the cymbal its unique voice and character.

Testing and Finishing Touches

After lathing, some cymbals undergo a polishing process to achieve the desired finish. Once complete, every single cymbal is sent for final testing.

Our product specialists meticulously inspect each one, performing both visual and audio tests to ensure it meets our rigorous quality standards. Cymbals that pass this inspection are then printed with our logos, followed by a thorough check of the graphics.

Once verified, our cymbals are ready to be enjoyed by drummers of all skill levels around the world. They are placed in our showroom and prepared for distribution to our partners, ready to become a part of someone’s musical journey.